Swivel forerunners are an essential tool used in various industries to transfer loads in different directions. They are particularly useful in heavy machinery, construction, and transportation sectors. Although swivel forerunners make work easier, it’s essential to be aware of the potential hazards they pose and the necessary safety precautions. This article will provide insights into the safety considerations to keep in mind when using swivel forerunners in a work environment.

Understanding Swivel Forerunners

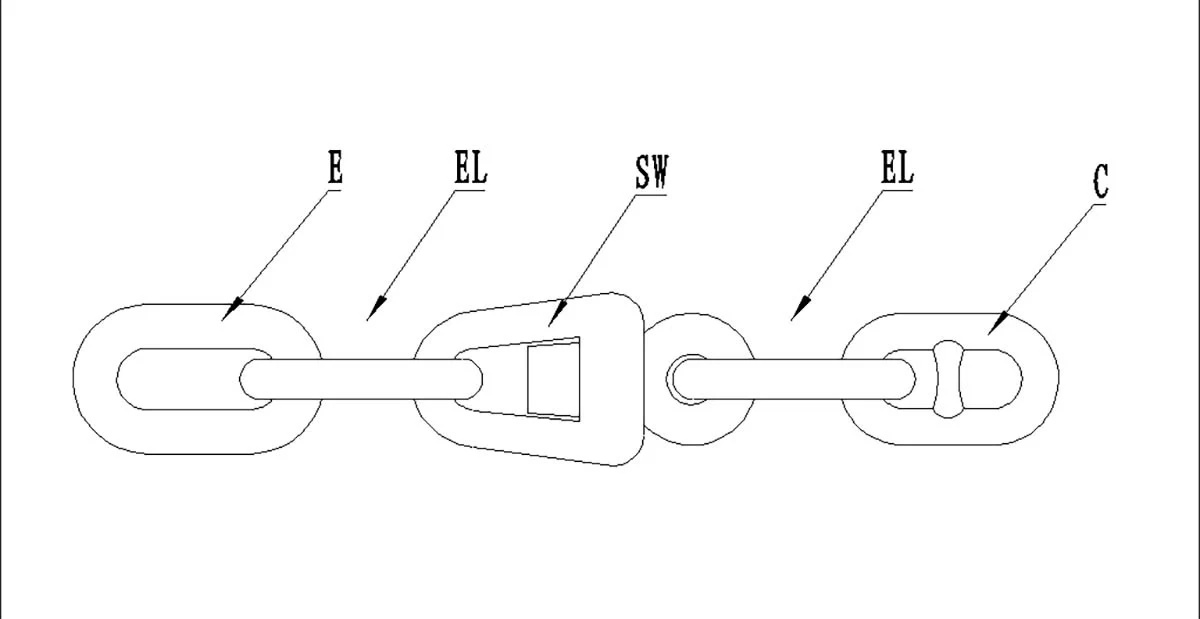

Swivel forerunners are devices used for moving heavy loads from one point to another. They are designed to rotate 360 degrees, allowing easy transfer of loads in different directions. They consist of a load-bearing hook that connects to the load and a swiveling device that allows the hook to move in different directions.

Identifying the Hazards of Swivel Forerunners

Despite the convenience and efficiency of swivel forerunners, they pose some hazards that can lead to workplace accidents. Some of these hazards include:

- Overloading: Swivel forerunners are designed to carry specific loads. Overloading can lead to damage, breakage, or failure of the device, causing accidents and injuries.

- Misuse: Using swivel forerunners for purposes they are not designed for can lead to accidents. For example, using a swivel forerunner to lift a load that is not compatible with the device can cause it to break or fail.

- Inadequate maintenance: Failure to maintain and inspect swivel forerunners regularly can lead to wear and tear, leading to accidents.

Safety Precautions When Using Swivel Forerunners

It’s essential to observe safety precautions when using swivel forerunners to prevent accidents and injuries. Some of the safety precautions include:

- Load Limitations: Adhering to the load limitations specified by the manufacturer can prevent overloading, which can lead to accidents and injuries. Before using a swivel forerunner, it’s essential to check the device’s load limits to ensure it is compatible with the load.

- Proper Use: Using swivel forerunners for their intended purposes is critical to safety. Operators should receive training on how to use swivel forerunners properly, including inspecting the device before use and avoiding using it for loads it is not designed to carry.

- Maintenance: Regular maintenance and inspection of swivel forerunners can prevent accidents and injuries. Operators should inspect swivel forerunners before use and report any signs of wear and tear to the relevant authorities.

- Protective Gear: Operators should wear the appropriate protective gear when using swivel forerunners, including hard hats, safety boots, and gloves, to prevent injuries in case of accidents.

Why Choose Our Swivel Forerunners?

At WAC-Corp, we prioritize safety and quality in all our products. Our swivel forerunners are manufactured to meet industry standards and are tested for durability and safety. We provide comprehensive training for operators to ensure they use our products safely and effectively. Additionally, our team of experts is available to provide maintenance and support services to ensure your swivel forerunners remain in optimal condition.

Conclusion

Swivel forerunners are an essential tool in various industries. They make work easier and improve efficiency. However, it’s essential to observe safety precautions when using swivel forerunners to prevent accidents and injuries. Operators should adhere to load limitations, use swivel forerunners for their intended purposes, perform regular maintenance and inspections, and wear appropriate protective gear.

Ensure your workplace is safe by using high-quality and reliable swivel forerunners. Don’t risk accidents and injuries by using substandard equipment. Choose quality, choose safety, choose WAC-Corp.

Related Products