Introduction

Anchor chain refers to robust metal chain used in mooring systems to secure vessels and floating structures. High strength and corrosion resistance allow anchor chain to withstand the demanding conditions of marine environments. It serves a critical function by maintaining position and providing holding power against currents, winds and tides.

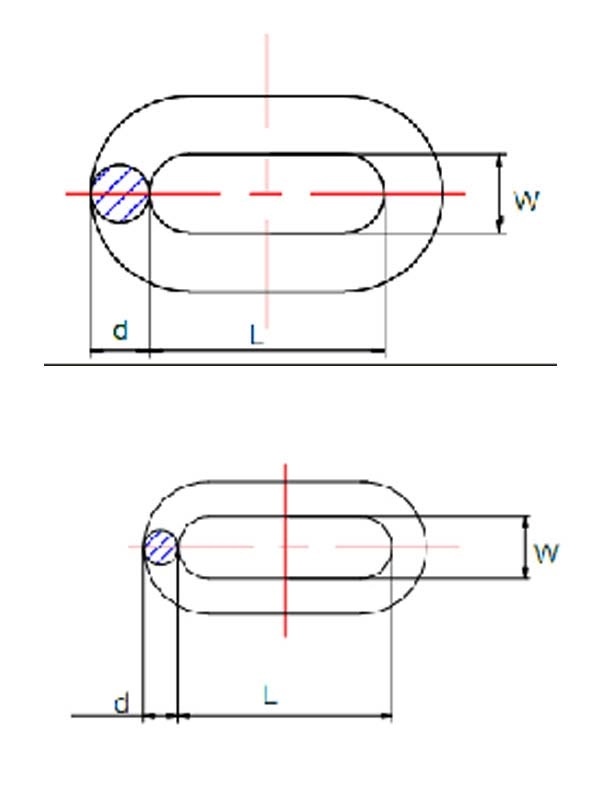

Anchor chain is produced from alloy steel and constructed using stud link or studless link designs. The chain assembly process involves forming wire or bar stock into links, welding the links together, and applying coating and treatments to resist corrosion.

High-quality anchor chain combines properties like:

- Extremely high tensile strength to handle heavy loads – The high carbon or alloy steels used in anchor chain have tensile strengths, allowing each link to withstand loads exceeding one ton without yielding. This gives the whole anchor chain assembly tremendous cumulative holding capacity.

- Ability to flex and self-adjust under strain – The articulated chain links provide flexibility to bend, twist, and adjust. This allows the chain to distribute forces and absorb shock loads. The flexibility helps minimize localized stress points.

- Excellent corrosion resistance from marine exposure – Hot-dip galvanization or other marine-grade coatings provide durable corrosion protection from continuous exposure to seawater. This maintains strength after years in harsh ocean environments.

- Long fatigue life with repeated or reversed bending – Anchor chains see constant motion and flexing under wave and tide forces. The steel and link geometries provide resistance to metal fatigue failure, enabling decades of cumulative fatigue life.

- Good abrasion resistance against seafloor or dock contact – The galvanized coatings and large radii link designs resist wear from abrasion when dragged across seabed or docks. This protects against degradation of the steel.

- The collective strength of the heavy chain links provides immense mass and holding power. Integrated studs, swivels and connectors allow the flexible anchor chain to be incorporated into mooring systems. By balancing all these factors, high-performance anchor chain resists the punishing marine environment forces for extended service life.

Applications

Anchor chain has wide usage across marine industries and structures owing to its extreme strength and durability in ocean environments.

Vessel and Ship Mooring

The primary application of anchor chain is securing ships and boats by connecting the vessel to anchors on the seafloor. The high tensile strength withstands strong winds, powerful currents, and tidal forces that act on the hull and superstructure. When combined with anchors and proper scope, anchor chain provides holding power to maintain position even in severe storms and surges. It also absorbs shock loads to reduce strain on the vessel. Bulk carriers, tankers, and large commercial vessels may utilize 300m or more of heavy anchor chain.

Offshore Platforms

On offshore oil/gas drilling platforms, production platforms, and related floating structures, anchor chain creates a robust mooring system to keep the platform on station. Multiple high-strength anchor chains extend in various directions, anchored to piles, suction caissons, or massive gravity anchors on the seabed. This secures the massive platforms against environmental loads. Anchor chain allows adjustments to re-center or rotate floating platforms as needed.

Harbors and Docks

Within harbors and ports, anchor chain is connected to heavy bollards or other strong points on docks, seawalls, and breakwaters. Ship captains can then tie mooring lines to the anchor chain when docking, allowing adjustment of the mooring configuration. The anchor chains can be sized and scoped appropriately to match different sizes of vessels. This provides reliable, flexible dock mooring.

Anchored Floating Barriers

Temporary floating barriers used in applications like harbor protection, marinas, oil containment, or event security utilize anchor chain to maintain their position. The chains extend from the floating barrier to anchors on the seafloor. This prevents the barrier from drifting away under wind/current loads. Having multiple anchor points allows quick repositioning or removal when needed.

Temporary Anchors

For temporary mooring of barges, construction floats, dredges and other vessels, lightweight anchor chain allows the rapid deployment of temporary anchors. Crew can quickly pay out the chain and drop anchors in the desired location. When finished, the anchors and chain can be easily recovered. This mobile anchoring with anchor chain saves time over fixed moorings.

Salvage Operations

In marine salvage operations, anchor chains serve as strong anchor points to refloat or position distressed vessels. Chains can be quickly attached and detached in order to pull, rotate or stabilize wrecks or sunken ships as needed for repositioning or refloating during complex salvage projects.

Purchasing Considerations

To ensure suitability for the severe marine conditions, buyers evaluating anchor chain should assess suppliers carefully based on criteria including:

- Capabilities to manufacture the chain diameters, stud designs and alloy grades needed for the vessel/application.

- Stringent quality control and compliance with marine standards to validate strength.

- State-of-the-art facilities and equipment to produce precision, consistent chain.

- Metallurgy expertise to recommend appropriate alloys and treatments for the operating environment.

- Understanding of mooring dynamics, scope ratios, and designs to optimize system performance.

- Integration of the entire production process from steelmaking through finished chain.

- Inventory availability of standard marine chain types to enable rapid fulfilment.

- Strong reputation producing high-performance anchor chain for marine applications.

- Documentation, traceability and packaging to maintain integrity during handling and storage.

Selecting anchor chain from a supplier focused on rigorous quality standards helps ensure the safety and security of vessels, structures, cargo and crew relying on its robust and reliable holding power in rough seas. With regular inspection and maintenance, high-grade anchor chain provides many years of enduring performance under the punishing conditions of marine mooring applications.

Summary

Anchor chain is a mission-critical component that secures vessels, platforms, and infrastructure against the immense forces of winds, waves, and currents. The safety and survival of ships, crews, and cargoes depend on the robust strength and holding power of their mooring systems, with anchor chain being the vital link. Through advanced metallurgy and manufacturing processes, today’s high-grade alloy anchor chains achieve an exceptional balance of extreme tensile strength, fatigue and corrosion resistance, abrasion resistance, and flexibility. They provide a reliable, long-lasting connection between floating structures and stable anchorage on the seafloor. Specifying anchor chain that consistently meets the most stringent marine standards ensures it can withstand decades of punishing marine environments while maintaining integrity. With regular inspections and proper maintenance, quality anchor chain continues playing its essential role securing assets and infrastructure in the harshest of ocean conditions. It provides the assurance that vessels and crews will ride out storms securely.

Related Products