Introduction

Long link chain refers to welded steel chain composed of elongated oval links that are longer in proportion compared to standard chain links. HDG (hot-dip galvanized) long link chain has gone through a hot-dip galvanization process to apply a protective zinc coating that enhances corrosion resistance and durability. HDG long link chain combines high strength with flexibility, making it useful for securing or lifting loads and transmitting pulling force in demanding environments.

Production Process

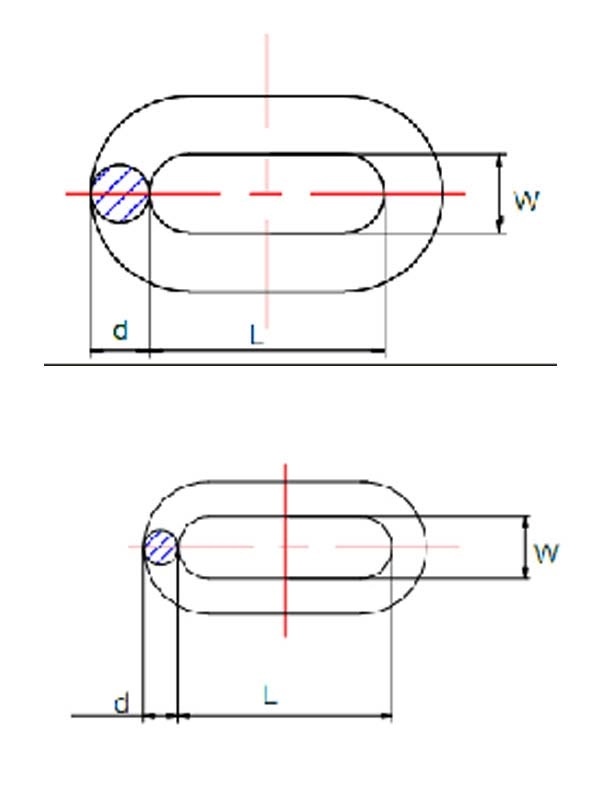

HDG long link chain starts with steel wire rod that is drawn into chain wire of the appropriate diameter to meet strength requirements. The chain wire is formed into links with an elongated oval shape and welded together using technologies like flash butt welding. This creates long pitch chain with larger openings between links.

Galvanization is done by dipping the assembled chain into a bath of molten zinc. The zinc reacts with the steel surface to form corrosion-resistant zinc alloy layers. HDG chain can also receive chromate treatment to further improve corrosion protection. The finished HDG long link chain is cleaned, tested and packaged to protect the zinc coating.

Material Properties

HDG long link chain is typically manufactured from high carbon steels or low/medium alloy steels. The steel provides a combination of strength, toughness and weldability. The elongated link shape and controlled tolerances result in key properties:

- Ability to flex in multiple planes and directions

- Lightweight proportional to strength

- Withstand repeated bending without fatigue

- Zinc galvanization provides corrosion resistance

Heavier duty chain can have double link construction. Customization of working load limits, link sizes and attachments can suit different requirements.

Applications and Usages

Key industries utilizing HDG long link chain include:

- Construction – Used with hooks, shackles, and fittings for lifting and securing structural components and heavy loads. Allows adjustable configuration and flexibility. Popular for concrete precast handling.

- Mining – Employed to lift and move materials throughout mining operations. Withstands heavy loads and abrasive environments. Used with specialized mining attachments.

- Marine – On docks and vessels, long link chain is integrated into mooring and towing systems due to combination of strength and flexibility. Resists corrosion from ocean exposure.

- Sports – Found in nets, barriers and other structures where flexibility and strength are valued. Used on football goal posts, baseball backstops, tennis court nets.

- Forestry – In logging applications, chain pulls cables used to move cut trees over long distances. Flexibility important when moving through wooded areas.

- OEM Applications – Integrated by equipment OEMs into cranes, winches, and other machinery needing strong, flexible chain systems.

HDG long link chain’s corrosion resistance, rugged durability, and high working load capacity make it ideal for heavy lifting, pulling, and securing in demanding conditions. Custom link size, strength grade and attachments allow adaptation into diverse systems across industries. With proper installation and maintenance, HDG long link chain provides decades of reliable service.

Quality Assurance and Specifications

To ensure HDG long link chain performs safely and reliably in demanding applications, manufacturers must adhere to strict quality control standards and specifications. This covers all aspects of production, from sourcing raw materials to final product testing and packaging.

Industry groups have developed various standards that define requirements for long link chain dimensions, steel grades, markings, test methods and inspection criteria. Compliance to applicable national and international standards provides assurance that the chain meets essential benchmarks for quality and performance.

Reputable HDG long link chain suppliers implement robust quality systems with procedures, documentation, and accountability at all stages. This starts with sourcing high quality steel wire rod feedstock that undergoes controlled drawing into chain wire. During link forming and welding, automation and monitoring ensures repeatable precision essential for chain integrity.

Galvanization bath chemistry and temperature must be maintained to guarantee sufficient zinc coating and penetration into the steel. Post-production testing via methods like tensile, impact and shot peening provides data to verify the chain’s strength and ductility. Finally, thorough final inspection and packaging preserves the chain quality.

By partnering with an HDG long link chain supplier that can provide documentation of quality systems, traceability, proof testing, and conformance to applicable standards, end users can be confident the chain will meet the most demanding application requirements for load capacity, service life and safety margins. This provides peace of mind that the chain performance will match design expectations.

Purchase Considerations

For buyers evaluating HDG long link chain, careful consideration should be given to ensure the product meets the technical requirements and quality standards for the intended application. Key aspects for buyers to research include:

- Manufacturing capabilities to produce the required link dimensions, steel grades, and load capacities. Customization may be necessary.

- Adherence to industry specifications and quality control practices to guarantee strength, zinc coating integrity and reliable performance.

- State-of-the-art facilities and equipment to achieve necessary precision, consistency and durability.

- Knowledgeable support to advise on appropriate specifications and design optimization for the expected usage conditions.

- Vertical integration of the entire production process from raw materials through finish quality checks.

- Availability of inventory for faster delivery when standard sizes can fulfill needs.

- Focus on continuous improvement to incorporate the latest technical upgrades.

- Experience successfully supplying chain for similar high-demand applications.

- Protective packaging and documentation to maintain quality in transit and storage.

By thoroughly evaluating suppliers against criteria important for application success, buyers can make informed sourcing decisions and have confidence in selecting HDG long link chain that will meet their most stringent requirements. With heavy loads and demanding conditions, using HDG long link chain from a qualified supplier ensures a robust solution that won’t let users down on the job.

Conclusion

HDG long link chain provides an optimal balance of flexibility, corrosion resistance and high strength. With capacities often exceeding 100 tons, it serves heavy-duty needs across construction, mining, marine, sports infrastructure and other industries. Ongoing advances in steel grades, coatings and manufacturing continue to extend possibilities, while research reveals new potential applications. HDG long link chain has proven itself as a versatile and reliable lifting, securing and pulling solution able to withstand the rigors of demanding real-world use.

Related Products